Flux

A modular IoT system of temperature monitoring and regulating wearables for blue collar industry workers.

Discipline

Industrial design,

User experience,

Interface design

Duration

10 weeks

(March - June 2020)

Team

Solo

According to the U.S. Bureau of Labor Statistics, “Exposure to environmental heat led to 37 work-related deaths and 2,830 nonfatal occupational injuries and illnesses involving days away from work in 2015.”

The Problem

The U.S. Occupational Safety and Health Administration’s (OSHA) accident records also contain summaries of thousands of temperature-related incidents: lumberjacks passing away from hypothermia, roofers suffering from heart attacks due to heat exhaustion, etc.

Impacted Industries

Blue collar jobs are typically classified as involving manual labor and compensation by an hourly wage. Some fields that fall into this category include construction, manufacturing, maintenance, and mining.

Workplace Requirements

work in direct sunlight (adds up to 15 degrees to heat index)

work in variable weather / climates

perform prolonged or strenuous work

wear heavy protective clothing or impermeable suits

prolonged exposure to heat-generating appliances

Potential Risks

heat stroke

heat exhaustion

heat cramps

heat syncope

heat rash

rhabdomyolysis

hypothermia

frostbite

trench foot

The Current System

“Under OSHA Law, employers are responsible for providing workplaces free of known safety hazards.”

This includes protecting workers from extreme temperatures.

Following OSHA guidelines, an employer should establish a “complete heat illness prevention program”:

provide workers with water, rest, and shade

allow workers to gradually acclimate to heat

plan for emergencies and train workers on prevention

monitor workers for signs of illness

However, there is no standard for how an employer should monitor or document this information.

Existing Solutions

For Employers + Managers

Extech Heat Watch

Heat, humidity, heat index, timing functions

No data logging function

Small, portable

Thermal Cameras

Visualize and measure body heat

No data logging function

Likely not in constant use

For Workers

Evaporative Cooling Bandana

Simple, inexpensive

Easy to wear under gear

Not effective for whole body use

Thermoelectric Gear

Individual components

Battery powered

Limiting / not adaptable

Current State

There are no standardized tools, monitoring systems, or documentation practices to ensure worker heat safety, across a variety of blue collar industries.

Overall Limitations

Inability to monitor workers unless at close proximity

Lack of documentation function

Current State

Besides personal protective gear and high-visibility vests, uniforms are not consistent within same profession.

Overall Limitations

Inability to regulate both temperature extremes

Inflexible solutions

Limited by specificity of wearable type

User Personas

Name, Age

Steve, 38

Occupation

Construction

Behaviors

Loads and unloads materials, tools, and equipment

Assists transport and operation of heavy machinery and equipment

Pain points

Extreme, sometimes unexpected temperature / weather variation

Dresses warmly for early morning start, but ends up overheating later

Unsure when / at what point physical discomfort requires attention

Name, Age

Tom, 43

Occupation

Behaviors

Manages several sites at once

Uses different software and connected devices to monitor information (e.g. Extech 42270)

Project manager

Pain points

Many logistical metrics to track; time-consuming and overwhelming

Difficult to monitor health / safety of individual workers

Lack of temperature monitoring, regulation, and awareness practices at job sites + variable climate conditions put blue collar workers at greater risk for temperature-related illnesses.

01

02

We should build...

a versatile product for blue collar industry workers to easily regulate their body temperatures while working in harsh, variable climates.

a system for blue collar industry employers to efficiently monitor and document workers’ body temperatures to ensure workplace safety.

Relevant Technology

Polyimide Thin-Film Heating Element

Ultra-thin, super flexible

Resistant to extreme temperatures, wear, and material corrosion

Can be any shape while maintaining uniform watt density

More evenly distributes heat compared to wire-element heaters

Temperatures up to ~130°F

OR Peltier Thermoelectric Plates

Can transmit both heating and cooling

Research is currently being done to integrate into wearables

Fairly thin, flexible

Temperatures ~40°F lower than ambient

Printed Thermistors

Small, ultra-thin, super flexible

Can be highly sensitive

Bluetooth / wireless connection to communicate monitored data

Ultra-low power consumption

7.4-Volt Lithium-Ion Battery

2.2 Ah ~ 5.2 Ah

Rechargeable and lightweight

Currently used in existing heating jackets

Various thicknesses, with as thin as ~8mm possible for 2.2 Ah

Active research and development in battery size reduction

The Concept

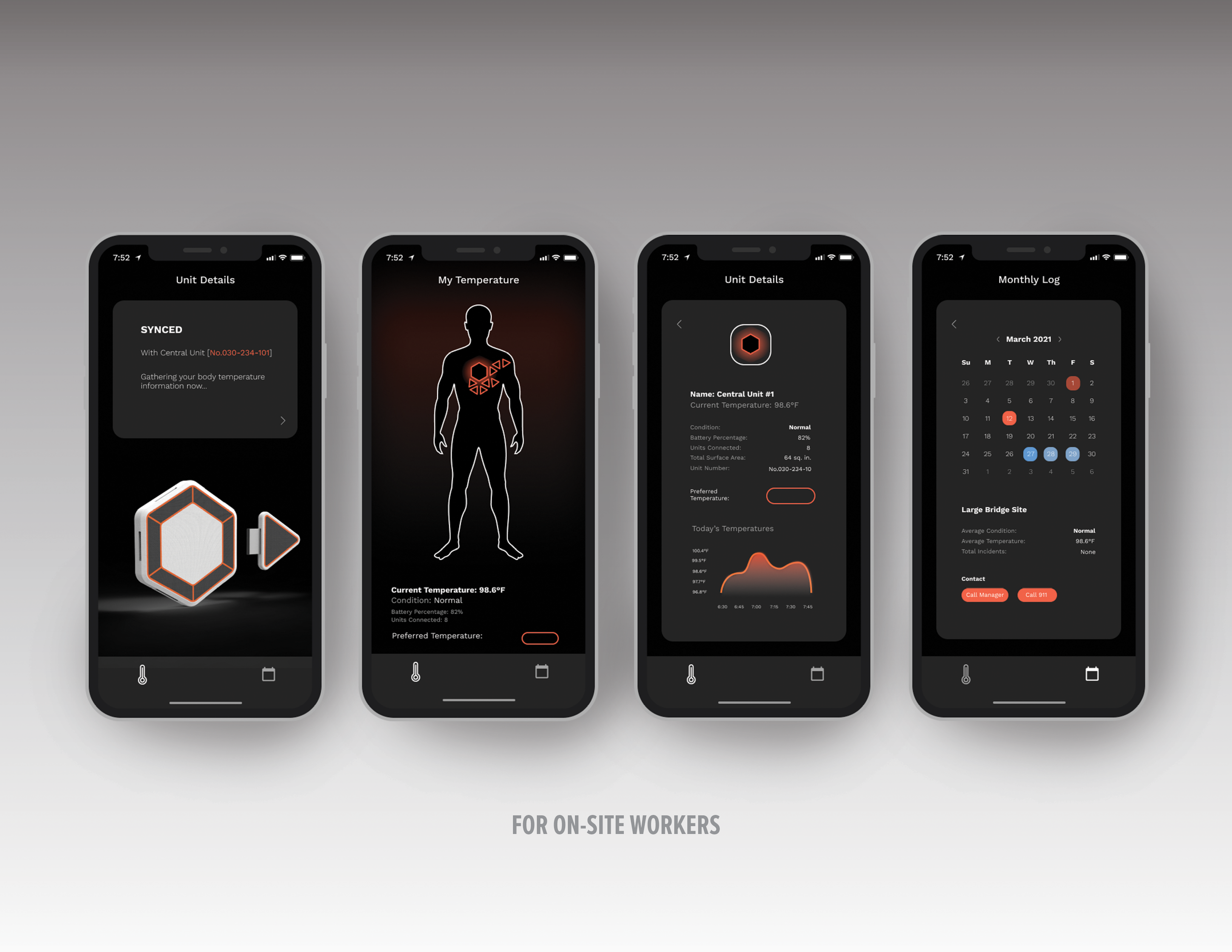

A system of temperature monitoring and regulation using modular wearable units (“patches”) connected to a mobile app.

Components

Power bank

Power distribution / central unit

Additional temperature regulation patch units to expand surface area coverage

Printed temperature sensors (built into patches)

Velcro adhesive backs for patches

App for data storage and temperature control

Form Development

Inspiration: Shapes that conform to body curvature and geometric tessellation patterns

Sketches

Organic shapes to better fit body and equipment

X shapes don't indicate modularity

Velcro attachment allows electronic components to attach to any clothing or gear

Velcro allows electronic components to be removable

Hexagonal central unit

Allows for multiple connections

Larger area for power bank

Triangular additional patches

Smaller surface area fits well on smaller body parts like hands

Needs many more units to cover more surface area

Data Flow

For Employers + Managers

For Workers

What is FLUX?

FLUX is a modular system of temperature monitoring and regulating wearables for blue collar industry workers at risk of temperature-related illness and their employers.

Adjusting Coverage

FLUX comes with 6 central units to cover key points on your body for temperature regulation: core/chest, hands, feet, and head.

Along with the central units, at least 6 additional patch units would be supplied to adjust surface area coverage.

A central unit has 6 connection points along its perimeter for additional patch units.

Each patch unit has one ribbon cable connector and ports on the remaining sides for additional unit connections.

Variable Configurations

Modular units cover user-specified locations and allow variation in the amount of surface area covered for completely customizable heating/cooling.

Components

1 - Bottom fabric layer w/ Velcro

2 - Elastomer shell latticed for flexibility

3 - Rechargeable power bank w/ case

4 - Circuit board

5 - Thin film heating element

6 - Film with printed thermistors

7 - Top fabric layer, interfaces with skin

Small, Thin, Flexible

By using thin film technology, FLUX units can be made extremely thin and small to fit comfortably under clothes and gear.

The elastomer containment piece's lattice pattern maximizes the flexibility and reach of each unit, allowing FLUX to move with the wearer.

CMF Recommendations

Shell Bodies

2 shot injection molded hard plastic (ABS) and elastomer (silicone) shells

black ABS, Hex #242424

grey silicone, Hex #E1E5EE

Fabric Layer

Cotton or similar

Soft, durable, absorbent, and breathable

Main body in grey Hex #E1E5EE

Accent color: black Hex #242424; orange Hex #FF6144; or blue Hex #586BA4